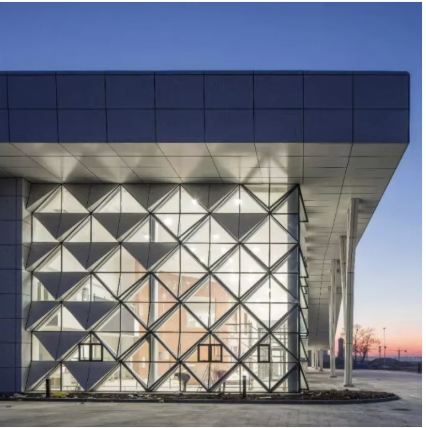

cambering steel beams

Cambering steel beams is a sophisticated process that involves the deliberate introduction of an upward curvature to counteract anticipated downward deflection under service loads. This pre engineering technique ensures optimal structural performance and maintains level surfaces once the full dead load is applied. The process typically employs heat or mechanical methods to create a precise upward bend in the beam, calculated based on expected loads and span requirements. Modern cambering techniques utilize advanced computer modeling and hydraulic systems to achieve precise measurements and curves. The applications of cambered beams are extensive, ranging from commercial building construction and bridge engineering to industrial facilities where maintaining level floors is crucial. The process requires careful consideration of factors such as load distribution, beam size, and material properties. Cambering is particularly valuable in situations where long spans are necessary or where architectural specifications demand minimal deflection. The technology has evolved significantly, now incorporating laser measurement systems and automated controls to ensure accuracy within millimeters. This precision engineering approach not only enhances structural integrity but also contributes to the overall efficiency and longevity of the construction project.