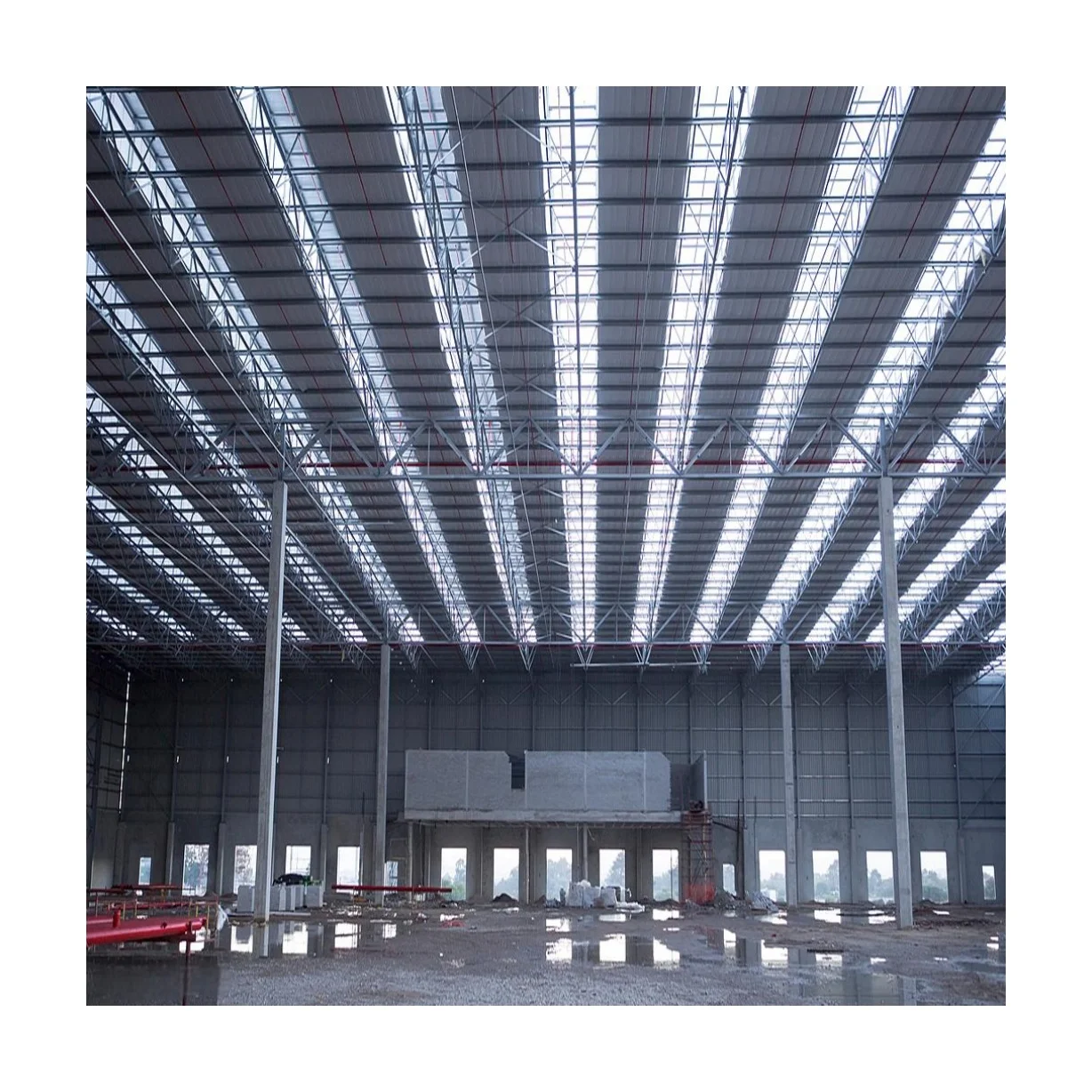

konstruksi fabrikasi baja

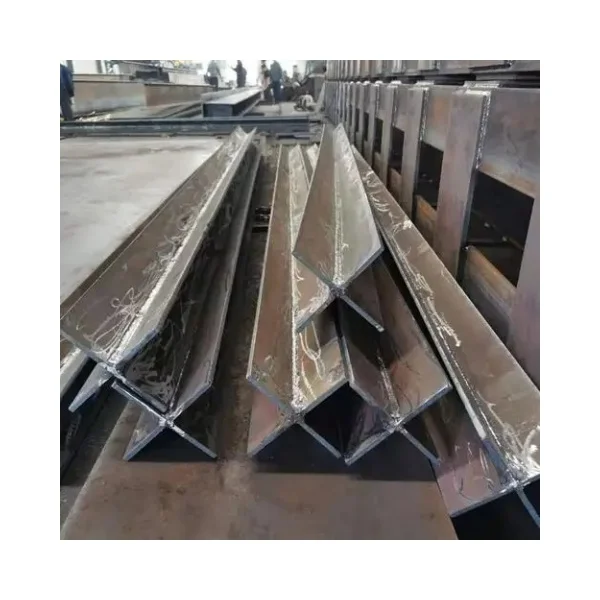

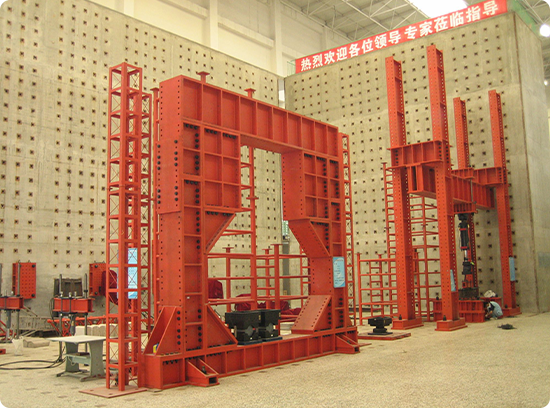

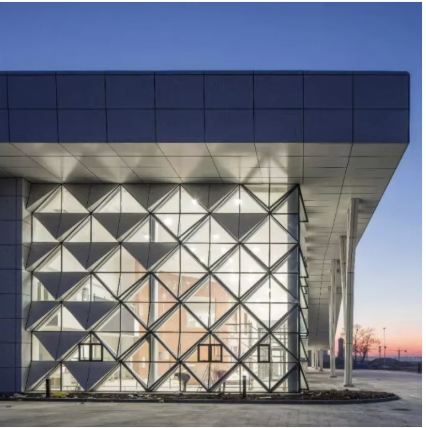

Konstruksi fabrikasi baja mewakili proses manufaktur yang canggih yang mengubah bahan baku baja menjadi komponen struktural yang presisi untuk berbagai proyek konstruksi. Proses komprehensif ini mencakup pemotongan, pembengkokan, pengelasan, dan perakitan elemen-elemen baja untuk menciptakan kerangka struktural yang kuat, elemen arsitektur, dan komponen industri. Fasilitas fabrikasi baja modern menggunakan teknologi canggih seperti mesin Computer Numerical Control (CNC), sistem pengelasan otomatis, dan perangkat lunak pemodelan 3D untuk memastikan akurasi dan konsistensi luar biasa. Proses ini dimulai dengan gambar teknik rinci dan spesifikasi, diikuti oleh pemilihan dan persiapan material. Teknisi terampil kemudian menggunakan berbagai teknik termasuk pemotongan plasma, pemotongan laser, dan mesin presisi untuk membentuk baja sesuai dengan persyaratan proyek. Langkah-langkah pengendalian kualitas diterapkan sepanjang proses fabrikasi, termasuk pengujian non-destruktif dan verifikasi dimensi, untuk mempertahankan kepatuhan ketat terhadap standar industri. Kebanyakan aplikasi dari fabrikasi baja meliputi berbagai sektor, termasuk gedung komersial, fasilitas industri, jembatan, dan pembuatan peralatan khusus. Metode konstruksi ini menawarkan rasio kekuatan-terhadap-bobot yang unggul, daya tahan yang sangat baik, dan kemampuan untuk membuat desain struktural kompleks yang memenuhi persyaratan proyek tertentu.