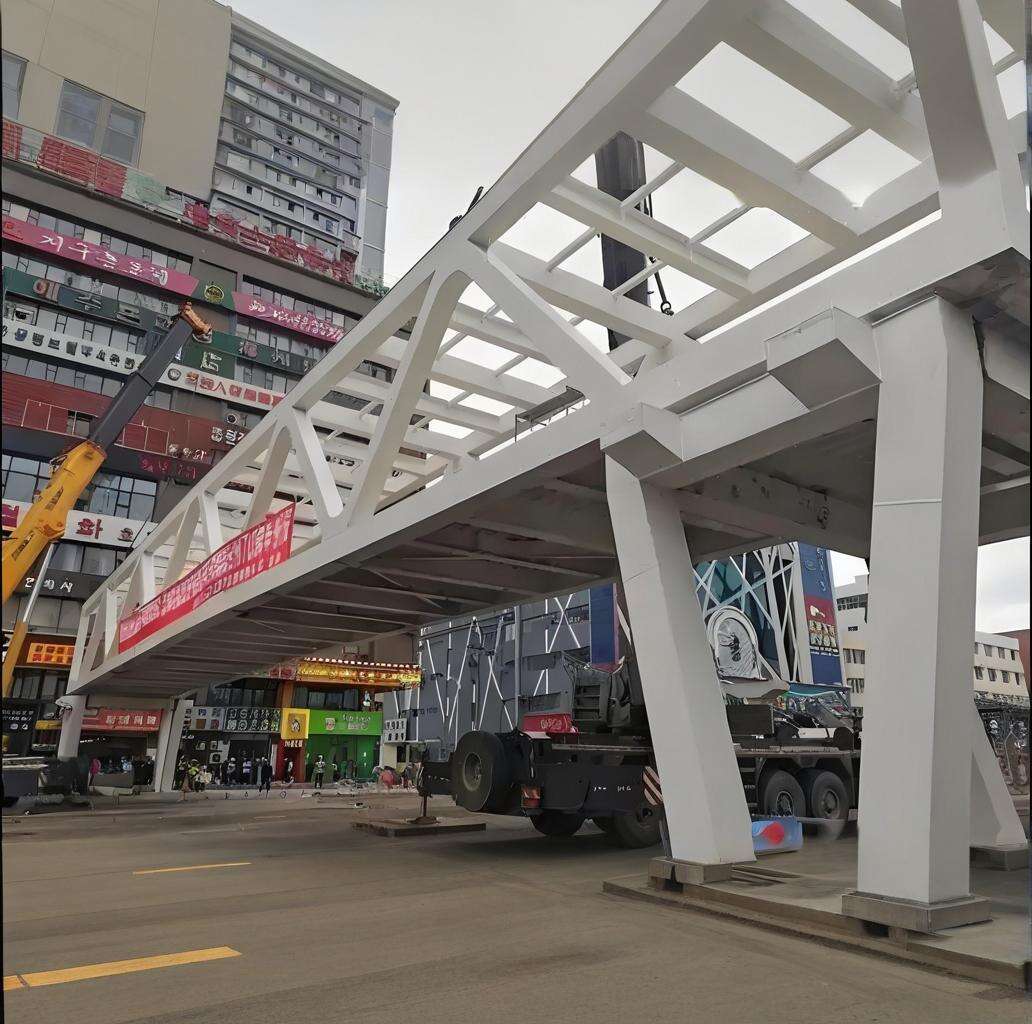

steel box girder bridge

A steel box girder bridge represents a sophisticated engineering solution in modern infrastructure design, combining structural efficiency with architectural elegance. This type of bridge consists of a hollow steel box section that serves as the main load-bearing element, typically featuring a rectangular or trapezoidal cross-section. The box girder structure efficiently distributes loads across its entire span while maintaining exceptional stability and durability. The design incorporates steel plates welded together to form a rigid box section, which carries both compression and tension forces effectively. These bridges can span significant distances while maintaining a relatively shallow structural depth, making them particularly suitable for situations where vertical clearance is critical. The interior of the box girder is accessible for maintenance and inspection, ensuring long-term serviceability. Modern manufacturing techniques allow for precise fabrication of components, resulting in high-quality construction and reduced installation time. These bridges commonly serve in highway overpasses, railway crossings, and urban viaducts, where their slim profile and structural efficiency make them an ideal choice. The design also allows for integration of utilities within the box section, maximizing functional space utilization.