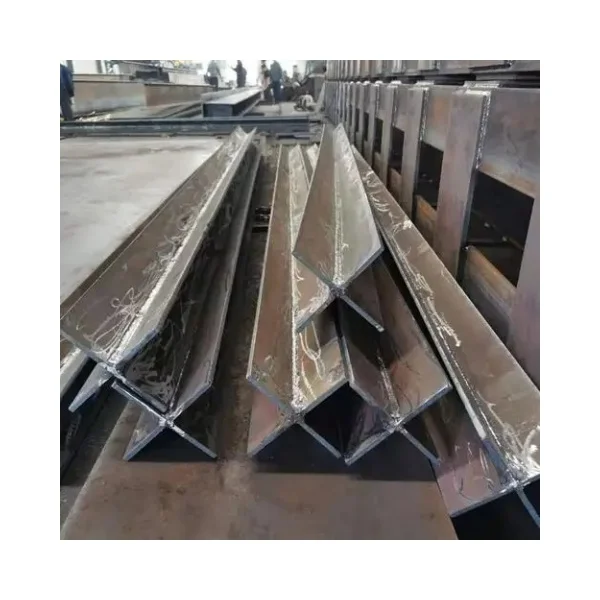

prefabricated steel bridge

A prefabricated steel bridge represents a cutting-edge solution in modern infrastructure development, combining efficient construction methods with robust engineering principles. These structures are manufactured off-site in controlled factory conditions, ensuring precise specifications and quality control throughout the production process. The bridge components are designed for optimal strength-to-weight ratios, utilizing high-grade steel that undergoes rigorous testing and treatment to ensure longevity and durability. The modular nature of these bridges allows for rapid assembly on-site, significantly reducing construction time and minimizing disruption to surrounding areas. These bridges can span various lengths and accommodate different load requirements, making them suitable for both vehicular and pedestrian traffic. The design incorporates advanced engineering features such as pre-stressed elements, specialized coating systems for corrosion resistance, and carefully calculated load distribution mechanisms. Modern prefabricated steel bridges often include integrated safety features, drainage systems, and can be customized with various deck materials to suit specific project requirements. They're particularly valuable in remote locations or areas where traditional construction methods might be impractical or cost-prohibitive. The standardized manufacturing process ensures consistent quality while allowing for customization to meet specific project requirements and local regulations.