light steel frame construction

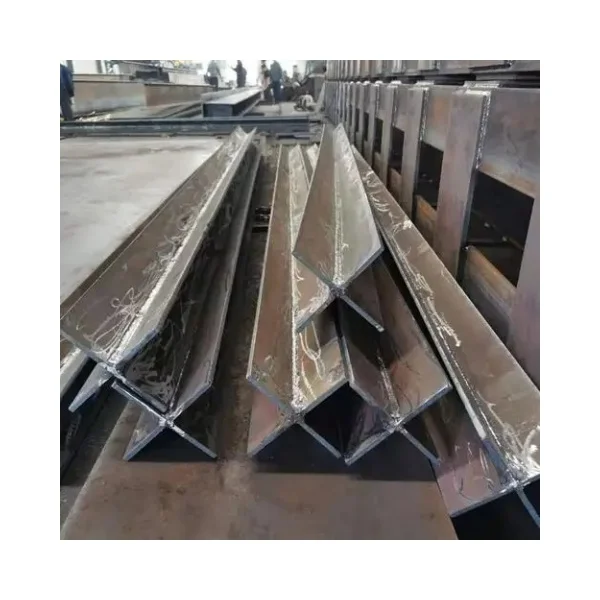

Light steel frame construction represents a modern building methodology that combines structural efficiency with sustainable design principles. This innovative construction system utilizes cold-formed steel members, typically ranging from 0.9 to 3.2mm in thickness, to create a robust skeletal framework for buildings. The system comprises precisely engineered components, including steel studs, tracks, joists, and trusses, all manufactured to exact specifications. These components work together to form walls, floors, and roof structures that distribute loads effectively throughout the building. The construction process involves assembling these lightweight yet strong steel sections on-site, creating a framework that serves as the building's primary support structure. Advanced galvanization techniques protect the steel elements from corrosion, ensuring long-term durability. The system accommodates various insulation materials and cladding options, offering excellent thermal performance and energy efficiency. Light steel frame construction finds extensive applications in residential buildings, commercial structures, educational facilities, and healthcare centers. Its versatility allows for both low-rise and multi-story construction projects, making it particularly suitable for areas with specific building height restrictions or challenging ground conditions.