l shaped steel beam

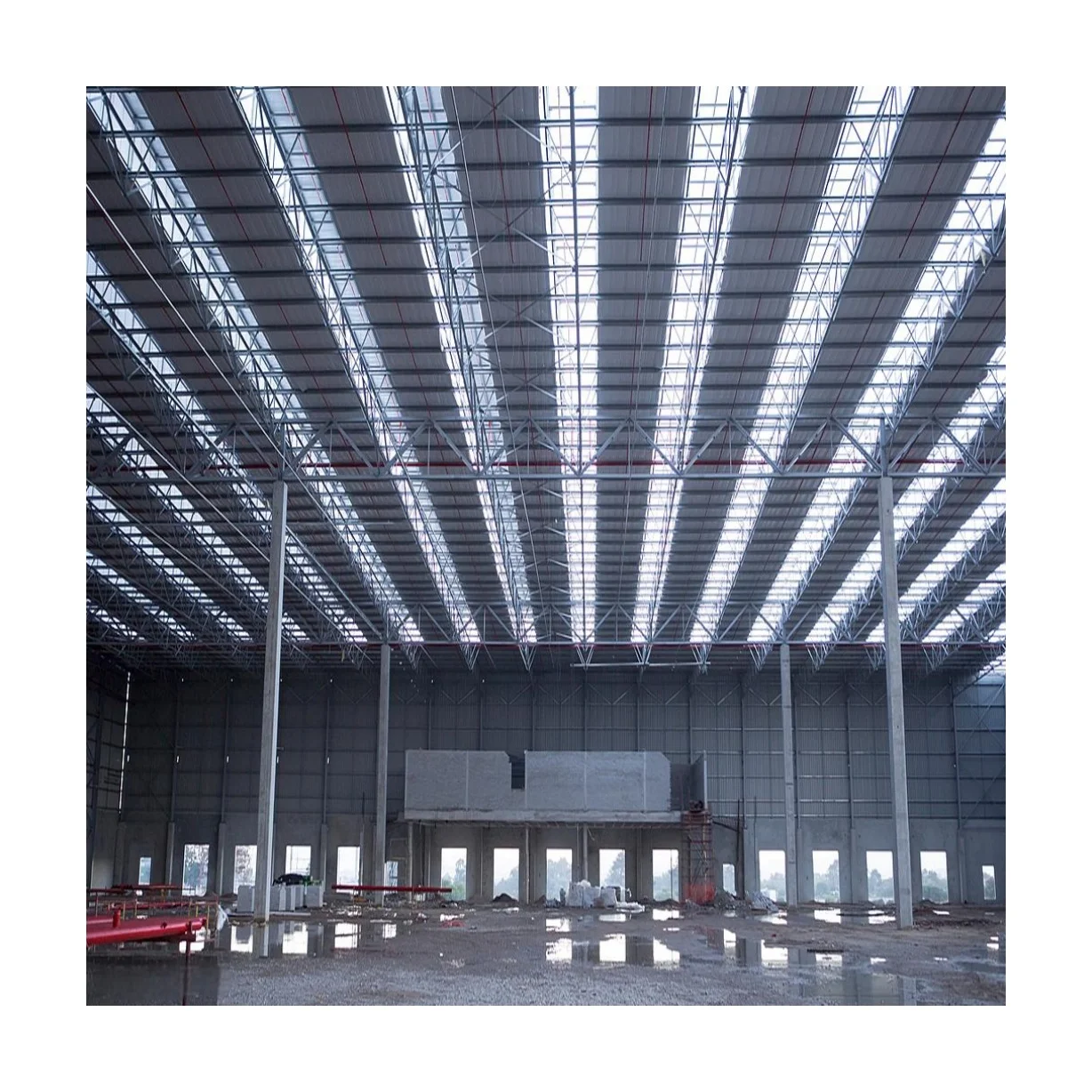

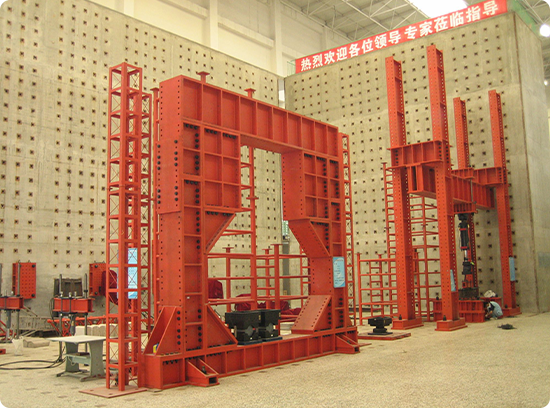

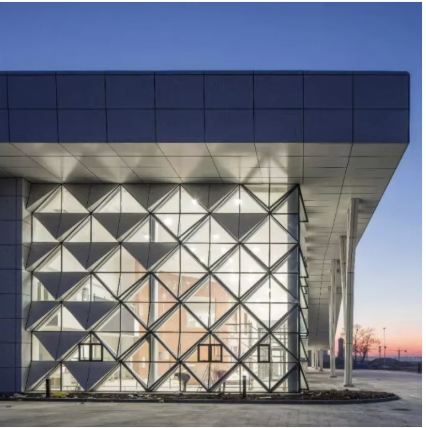

The L shaped steel beam, also known as an angle iron or steel angle, is a fundamental structural element in modern construction and engineering. This versatile component features two perpendicular flanges forming a 90-degree angle, creating its distinctive L shaped profile. Typically manufactured through hot rolling processes, these beams are available in various sizes and thicknesses to accommodate different load-bearing requirements. The L shaped steel beam excels in providing robust support and stability in both vertical and horizontal applications. Its design allows for efficient load distribution while maintaining structural integrity across diverse construction scenarios. These beams are manufactured according to strict international standards, ensuring consistent quality and reliable performance. They commonly feature precise dimensional tolerances and undergo rigorous testing for strength and durability. The applications of L shaped steel beams span across multiple industries, from building construction and infrastructure development to manufacturing and industrial installations. They serve as essential components in framework construction, support structures, bracing systems, and architectural applications. Their versatility makes them particularly valuable in projects requiring both structural strength and design flexibility.