industrial steel frames

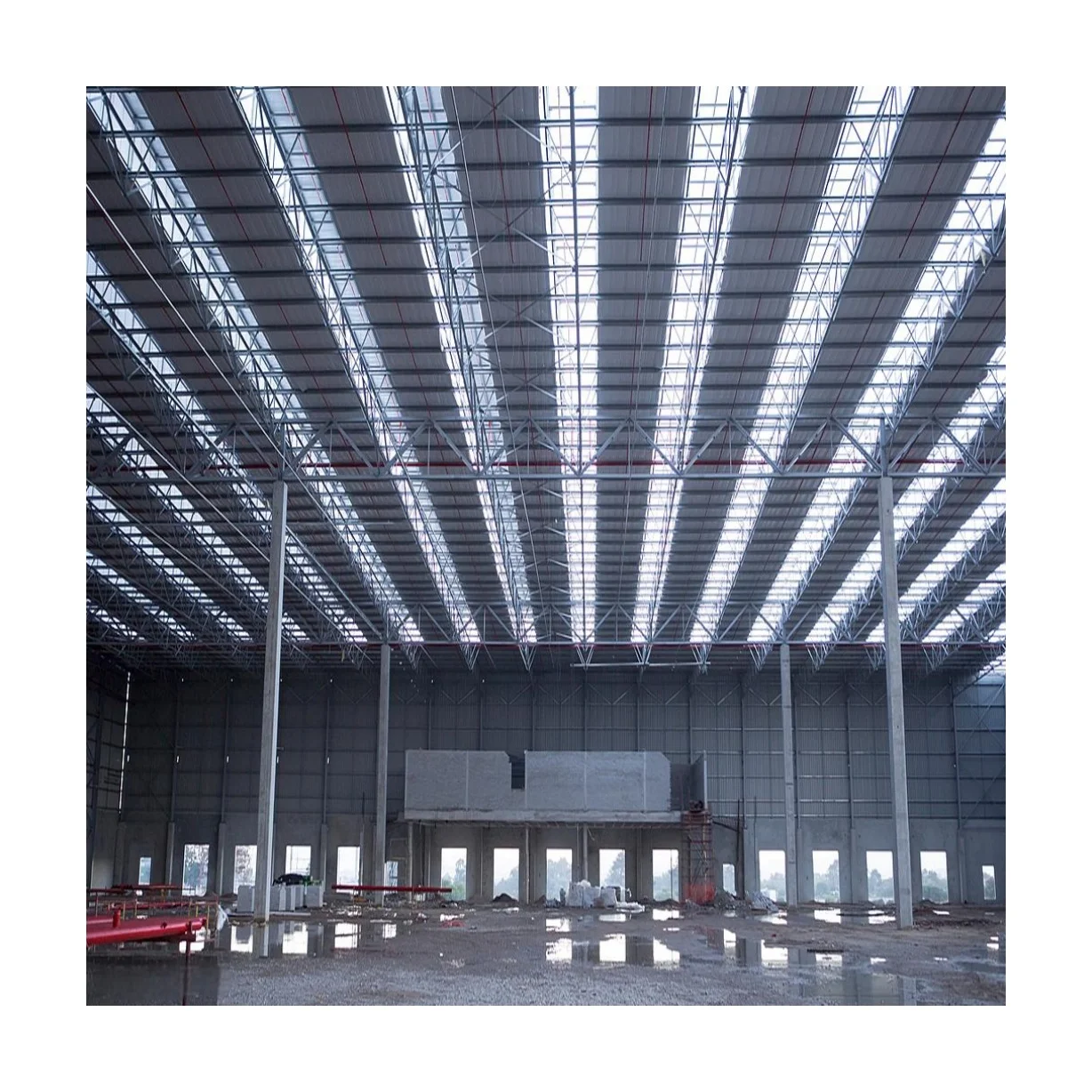

Industrial steel frames represent the backbone of modern construction and manufacturing infrastructure. These robust structural components are engineered to provide exceptional strength and stability while maintaining cost-effectiveness and versatility in various applications. Manufactured using high-grade steel alloys, these frames are designed to withstand extreme loads, environmental pressures, and long-term wear. The frames feature precision-welded joints, reinforced connection points, and advanced corrosion-resistant coatings that ensure longevity. They serve multiple functions, from supporting heavy machinery in manufacturing facilities to forming the skeleton of large commercial buildings. The technological features include modular design capabilities, allowing for easy customization and expansion, integrated cable management systems, and compatibility with various cladding materials. These frames are particularly valuable in industrial settings where reliability and durability are paramount. They can be configured to accommodate specific equipment requirements, overhead crane systems, and mezzanine floors. The frames also incorporate modern safety features, such as fire-resistant coatings and seismic resistance capabilities, making them suitable for various geographical locations and regulatory requirements.