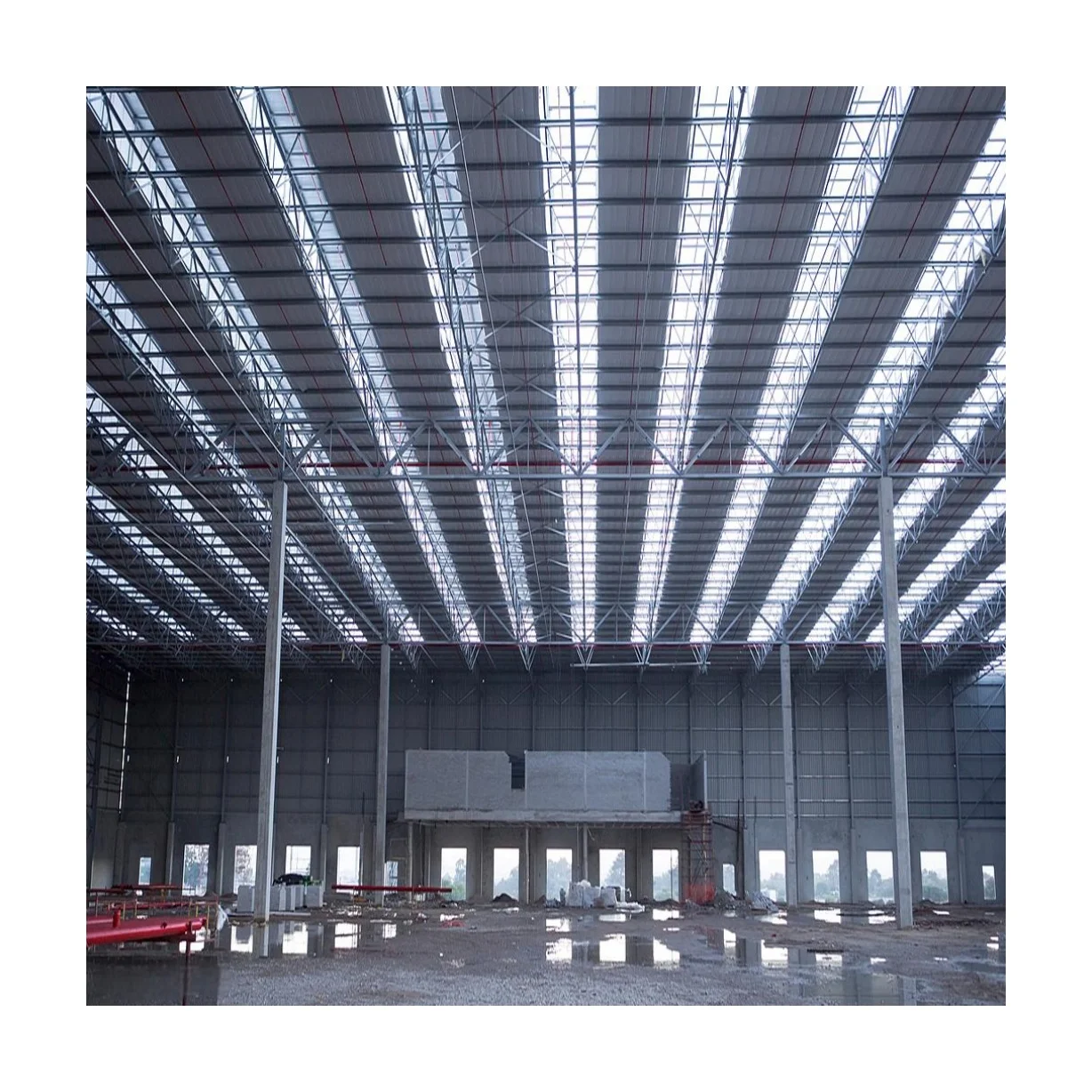

galvanized steel building

A galvanized steel building represents a pinnacle of modern construction engineering, combining durability with versatility. These structures undergo a specialized coating process where steel components are dipped in molten zinc, creating a protective layer that shields against corrosion and environmental damage. The galvanization process penetrates the steel at a molecular level, forming a metallurgical bond that provides superior protection compared to traditional painting or coating methods. These buildings feature precision-engineered components, including galvanized steel frames, panels, and fasteners, all designed to work together seamlessly. The structures can span wide areas without intermediate supports, making them ideal for commercial, industrial, and agricultural applications. Modern galvanized steel buildings incorporate advanced design elements such as energy-efficient insulation systems, customizable door and window placements, and flexible interior layouts. The engineering behind these buildings ensures they meet or exceed local building codes while providing optimal resistance to wind, snow, and seismic forces. This construction method allows for rapid assembly, reducing on-site construction time and associated costs while maintaining exceptional structural integrity and longevity.