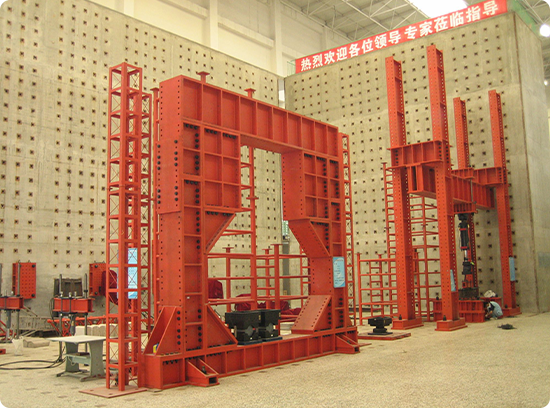

tunel Makinesi Kalkan Reaksiyon Çerçevesi

Kalkan tunel makinesi tepki çerçevesi, modern tunelleme işlemlerinde kilit bir bileşendir ve tunelleme kazı makinalarının verimli ve hassas çalışmasını sağlayan ana destek yapısıdır. Bu dayanıklı mühendislik harikası, kalkan makinesinin çeşitli jeolojik yapılar aracılığıyla ilerlemesi için gerekli temel itme kuvvetini sağlar. Tepki çerçevesi, devasa basıncı dayanabilen yüksek dayanımlı çelik bileşenlerin sofistike bir montajından oluşur ve yapısal bütünlüğü korurken bu basıncı karşılar. Çerçeve, tunelleme işlemleri sırasında üretilen reaktif kuvvetleri etkili bir şekilde tunelleme kaplama segmentlerine aktarır ve sürekli ilerleme için kararlı bir platform oluşturur. Çerçeve, itme kuvveti üzerinde kesin kontrol sağlamak için gelişmiş hidrolik sistemlere sahiptir ve optimal kesim performansını ve yönlendirme doğruluğunu sağlar. Modüler tasarımı, dar alt zemin alanlarında kolay montaj ve demontaj imkanı sunarken, korozyona direnç gösteren malzemeleri uzun ömürlülük için zorlu çevresel koşullarda güvence altına alır. Tepki çerçevesi ayrıca yapısal yükler ve işletim parametreleri hakkında gerçek zamanlı veri sağlayan entegre güvenlik mekanizmaları ve izleme sistemlerine sahiptir, bu da önleyici bakım ve risk yönetimi için olanak sağlar.