щитовая машина для тоннелепроходческих работ с металлической опорной рамой

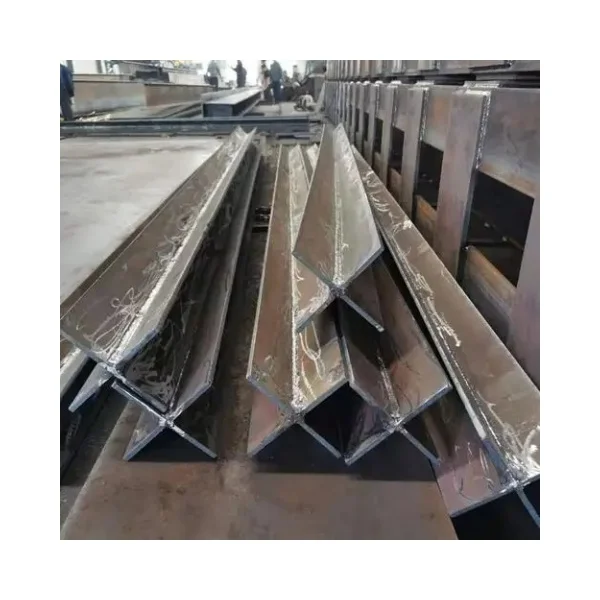

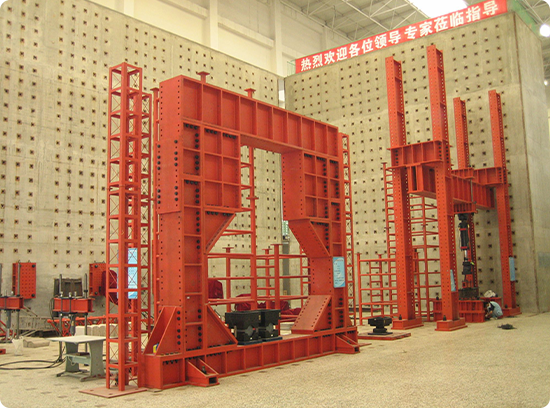

Каркас из стали для щитового тоннелепроходческого механизма является ключевым элементом в современной технологии строительства туннелей, служа опорой всего процесса проходки. Этот прочный конструктивный каркас обеспечивает необходимую поддержку и устойчивость щитовому тоннелепроходческому механизму во время процессов выемки грунта. Каркас изготовлен из высокопрочных стальных компонентов, предназначенных для выдерживания интенсивного давления и напряжения, сохраняя при этом оптимальную операционную эффективность. Он имеет сложный модульный дизайн, что позволяет быстро собирать и разбирать его, что критически важно для транспортировки и установки на различных строительных площадках туннелей. Опорный каркас включает в себя передовые системы несения нагрузки, которые равномерно распределяют вес по нескольким точкам, предотвращая концентрацию структурных напряжений. Он также оснащен механизмами точной регулировки, обеспечивающими правильное позиционирование тоннелепроходческой машины и поддержание правильной траектории на протяжении всего процесса бурения. Каркас включает встроенные системы безопасности, такие как усиленные точки соединения и аварийные опорные системы. Его универсальный дизайн адаптируется к различным диаметрам туннелей и условиям грунта, делая его подходящим для различных требований проектов. Структура защищена передовыми антикоррозийными покрытиями, что увеличивает срок её службы в сложных подземных условиях.