Évaluation des besoins de votre entreprise pour la conception de structures en acier

Définir le but de votre Structure en acier

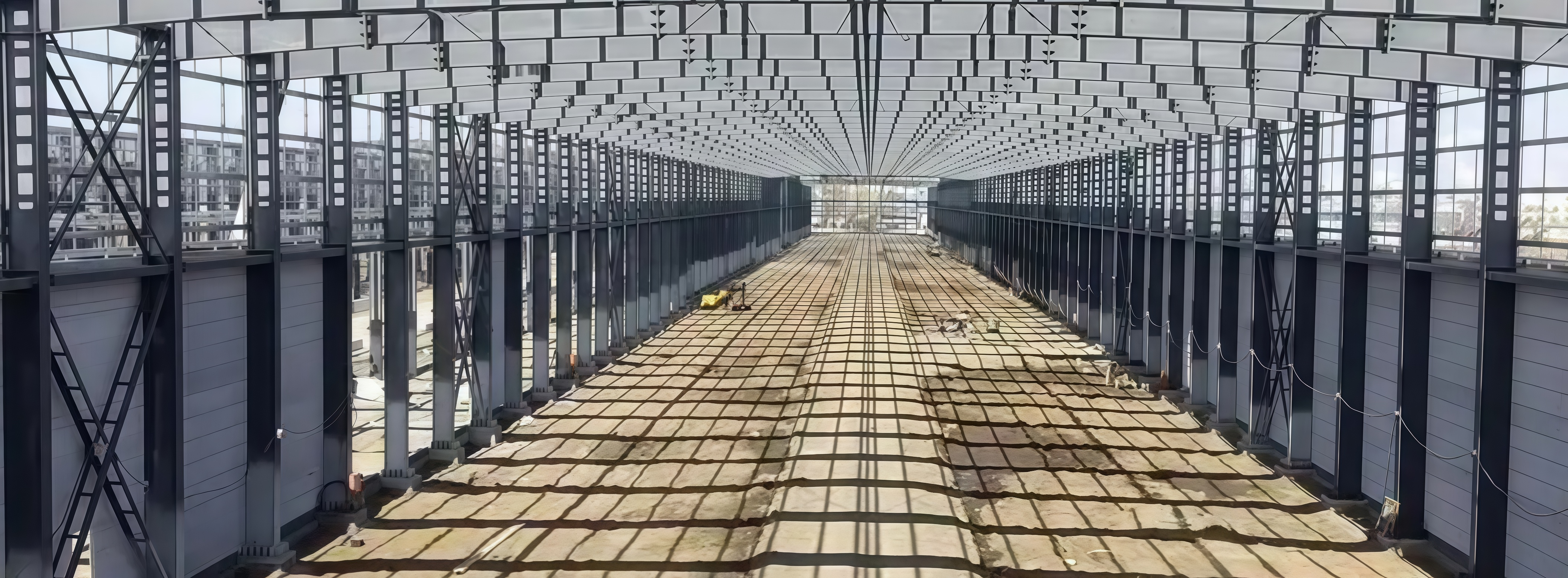

La première étape de la conception de structures en acier consiste à décider de la finalité globale de la structure. Que le bâtiment soit destiné à une utilisation commerciale, industrielle ou résidentielle influencera grandement sa conception. Prenons l'exemple d'un entrepôt qui nécessite des exigences différentes d'un garage. Il est toujours important de penser à l'avenir en tenant compte des besoins actuels et possibles futurs pour répondre aux exigences d'agrandissement actuelles et futures. En planifiant à long terme, cela permet de garder vos conceptions agiles et flexibles afin qu'elles n'aient pas besoin de modifications majeures à une date ultérieure. Cela va au-delà d'une simple manière d'inclure les parties intéressées dans le développement d'un service dès le début du projet ; faire cela est également un bon moyen de s'assurer qu'il y ait au moins une opportunité formelle pour que la conception d'un service soit intégrée à l'entreprise, avec une stratégie cohérente basée sur ce que tout le monde souhaite.

Évaluation des exigences opérationnelles actuelles versus futures

Une analyse approfondie des opérations existantes est nécessaire pour déterminer les exigences et les limites en matière d'espace dans la planification d'une conception de bâtiment en acier. Cela doit également inclure une analyse du flux de travail actuel et des besoins en stockage, afin que le nouveau disque dur ne se remplisse pas. Et estimer les changements potentiels dans les opérations futures, par exemple la croissance de la main-d'œuvre ou l'augmentation de la production, est essentiel pour prédire les exigences structurelles. En comparant ces projections avec les normes de l'industrie, nous pouvons déterminer si les conceptions proposées sont non seulement compétitives, mais également prêtes à répondre aux futurs besoins. Cette réflexion prospective est la clé pour concevoir une charpente en acier parfaite non seulement pour les besoins actuels, mais aussi pour toute expansion future.

Analyse des besoins en portance et en utilisation de l'espace

Il est essentiel d'étudier en profondeur les charges, c'est-à-dire quels sont les poids et contraintes que votre structure en acier doit supporter. La connaissance des capacités portantes orientera le choix des matériaux et des solutions techniques permettant d'assurer la sécurité structurelle. En parallèle, l'établissement précis des plans des étages permet une meilleure utilisation de l'espace et une circulation efficace à l'intérieur du bâtiment. C'est ici qu'une discussion avec un ingénieur structural peut s'avérer inestimable, car il peut offrir les meilleures recommandations pour concilier les paramètres de conception avec les exigences de performance et de sécurité. Cet effort collectif garantit également que la charpente métallique est adaptée à son usage tout en respectant les normes de sécurité, ainsi qu'optimise l'installation industrielle.

Facteurs Spécifiques au Lieu dans la Construction de Structures en Acier

Considérations Climatiques : Charges dues au Vent, à la Neige et aux Séismes

L'impact du temps : Lorsqu'on construit avec de l'acier, il est essentiel de savoir quel impact le climat aura sur votre bâtiment pour garantir sa durabilité et sa sécurité. Il est nécessaire d'étudier les données climatiques historiques afin de déterminer les conditions météorologiques les plus sévères auxquelles nous devons concevoir le bâtiment. Par exemple, les trajectoires du vent, la charge de neige et les éventuels séismes sont des facteurs importants à considérer dans les charges structurelles. Déterminer des coefficients de charge appropriés est crucial pour résister à ces forces environnementales et respecter les normes de sécurité. De plus, l'inclusion de caractéristiques résilientes (comme des éléments renforcés ou des conceptions ductiles) peut considérablement augmenter la résistance du bâtiment en acier face aux conditions environnementales dommageables.

Analyse du terrain et stabilité du sol pour les structures en acier

Le type de terrain et la stabilité doivent être étudiés de près avant que les travaux de construction ne puissent commencer. Grâce aux relevés géologiques, nous apprenons les propriétés du sol et la charge qu'il peut supporter, ce qui affecte directement le dimensionnement correct de la fondation. En analysant le terrain, nous pouvons prévoir et résoudre tout problème susceptible de survenir dans la logistique de construction et la stabilité du bâtiment. Établir une fondation ~ La fondation est adaptée à la condition du sol afin que le poids soit transféré efficacement à la structure en acier. Ce respect du territoire et de la nature du sol assure non seulement une stabilité parfaite pour le bâtiment, mais aussi sa durée de vie plus longue et sa sécurité.

Réglementations locales de construction et normes environnementales

Se conformer aux normes locales de construction et aux réglementations environnementales est un aspect crucial de la construction en acier. "Donc, si je peux vous l'illustrer, chercher et apprendre ces normes nous aidera à garantir que notre projet respecte les exigences des structures en acier. De plus, les lois environnementales peuvent exiger des matériaux et des méthodes de construction spécifiques, influençant ainsi la conception et la mise en œuvre. Travailler avec les gouvernements locaux dès le début du processus de planification peut aider à assurer une certaine certitude et à éviter les problèmes juridiques. En comprenant et en suivant ces lignes directrices, non seulement obtenons-nous de l'aide pour nous assurer que nous restons hors de tout problème et exempt de pénalités, mais nous ajoutons également quelque chose de positif à l'atmosphère réglementaire de la communauté.

Sélection de matériaux en acier et de revêtements de haute qualité

Comprendre les qualités d'acier pour les applications commerciales

Il est important de connaître les différents grades pour les applications commerciales lorsqu'on choisit l'acier. Les grades d'acier utilisés, tels que A36, A500 et A992, ont chacun des caractéristiques spécifiques et offrent un certain type de valeur pour la construction qui les produit. Par exemple, l'A36 est le plus couramment utilisé, tandis que l'A500 offre une haute résistance à la contrainte, ce qui en fait un choix pour les applications portantes nécessitant une charge importante. Cette différence entre haute résistance et résistance standard n'est pas négligeable lorsque l'on considère qu'elle peut affecter les performances et le coût d'un projet. La certification, comme celle de l'ASTM, est importante pour certifier la sécurité et la qualité. Cela assure que l'acier utilisé pour la construction est de la plus haute qualité et continue de maintenir une sécurité et une force maximales.

Revêtements résistants à la corrosion pour la longévité

L'enduit protecteur est essentiel pour prolonger la durée de vie des structures en acier en résistant à la corrosion. Différents types de revêtements, tels que le galvanisé, le revêtement en poudre et la peinture, offrent chacun leurs propres avantages. Par exemple, le galvanisé assure une protection robuste contre les conditions météorologiques extrêmes pour les bâtiments extérieurs, tandis que le revêtement en poudre offre durabilité et esthétique. Avec les meilleurs finitions, vous réaliserez non seulement des économies à long terme, mais il y aura également moins d'entretien et de réparations nécessaires. De plus, les revêtements sur une structure doivent être choisis en tenant compte de l'environnement dans lequel cette structure est située, car cela peut jouer un grand rôle dans la durée pendant laquelle l'investissement pourrait prospérer, ainsi que dans la protection de cet investissement contre les facteurs environnementaux dommageables.

Solutions en acier résistant au feu pour une sécurité renforcée

Les systèmes en acier résistants au feu sont essentiels pour préserver l'intégrité des bâtiments lors d'urgences liées au feu. De telles solutions incluent, par exemple, des revêtements intumescents qui augmentent de volume lorsqu'ils sont chauffés afin de fournir une couche protectrice, ainsi que des panneaux ignifuges haute performance qui offrent une isolation pour les éléments en acier. Les exigences en matière de sécurité incendie expliquent les exigences de sécurité contre l'incendie pour tous les lieux de travail dont l'employeur est responsable dans une publication pratique et facile à lire : Exigences en matière de sécurité incendie pour le secteur commercial et industriel maxsupport/l5 1,4 Mo 58 pages. Cela s'adresse principalement au secteur commercial et industriel. L'utilisation d'options classées feu a l'avantage de protéger le bâtiment et de réduire les risques tout en augmentant la sécurité des personnes à l'intérieur. Ces systèmes ne répondent pas seulement aux exigences de protection contre l'incendie, mais contribuent également de manière essentielle à la capacité de la construction à résister aux contraintes auxquelles elle est soumise en cas d'incendie, protégeant ainsi à la fois le bâtiment et ses occupants.

Conformité de l'ingénierie et de la conception pour la sécurité structurelle

Collaboration avec des ingénieurs structures certifiés

Travailler avec des ingénieurs structures agréés est essentiel pour les projets de construction afin de rester dans le cadre de la conformité et des réglementations de sécurité. La collaboration avec des personnes qualifiées, évaluant le bon moment en fonction de vos besoins, peut aller des matériaux sophistiqués à l'ingénieur en chef. Prenez connaissance du cabinet d'ingénierie Avant d'embaucher une entreprise d'ingénierie, il ne faut jamais oublier de consulter leur portfolio, lire les témoignages des clients précédents et vérifier leurs qualifications. Meilleures pratiques de communication Permettre la collaboration pour partager des idées franchement et soulever des préoccupations dès le début, tant dans les processus de conception que d'implémentation. L'importance d'un bon partenariat avec des ingénieurs structures pour aider à atteindre les objectifs de sécurité d'un projet ne peut être surestimée.

Calcul de charge et conception d'articulations sans couture

Des calculs de charge appropriés sont la clé pour construire un bâtiment sûr et solide. Les concepteurs utilisent des formules sophistiquées pour calculer combien de contrainte votre structure de bâtiment doit être capable de supporter - du poids de votre bâtiment aux forces de la nature sur la structure - et bien d'autres aspects. L'articulation est également bien conçue pour une structure robuste. Les articulations doivent être conçues pour permettre le mouvement et pour assurer le transfert adéquat des charges, limitant ainsi la création de points de contrainte possibles. Une conception rationnelle des connexions entre les éléments peut non seulement optimiser la procédure de montage, mais aussi améliorer la qualité du travail en acier et la longévité du bâtiment.

Se conformer aux Normes Internationales de Construction (par ex., AISC)

Se conformer au code de construction national/international (par exemple, AISC, 2016) est une exigence stricte en matière de construction et a des implications directes sur la réussite du projet. Ces normes établissent des spécifications concernant les matériaux, la conception, l'assemblage et la qualité, qui sont soumises à des critères rigides en matière de sécurité et de fiabilité. Le respect des lignes directrices publiées peut prévenir des modifications coûteuses et même réduire les risques pour la sécurité pendant la durée du projet. À l'inverse, ne pas se conformer peut entraîner des échecs structurels, des poursuites judiciaires et des coûts inattendus. La conformité aux normes garantit que la construction répondra aux exigences réglementaires et augmentera la confiance dans la structure.

Personnalisation et anticipation de votre ossature en acier

Conception modulaire pour une expansion évolutif

Un cadre en acier et un concept de conception modulaire sont nécessaires pour les mises à niveau et extensions futures. Cette conception offre la possibilité aux entreprises de développer leur structure sans investir dans de grandes rénovations - une flexibilité sans égale. Différents systèmes modulaires comme des éléments en acier préfabriqués permettent l'évolutivité et la personnalisation. Ces systèmes sont disponibles en une variété de configurations et de tailles, afin que les entreprises puissent choisir les options les plus adaptées à leurs contraintes d'espace et à leurs besoins opérationnels. Dans un environnement commercial en constante évolution, les cadres modulaires sont un facteur critique de succès, offrant des outils puissants qui permettent aux entreprises de s'adapter rapidement aux nouveaux besoins opérationnels et aux changements du marché.

Fonctionnalités adaptables pour des opérations commerciales en évolution

Il est important de mettre en œuvre des fonctionnalités flexibles dans la structure en acier pour satisfaire aux exigences changeantes des bureaux. Avec la technologie moderne – y compris des cloisons mobiles, des agencements de planchers flexibles et des panneaux Andon numériques à faible coût – le réaménagement des espaces peut être rapide et coûteux pour les entreprises réticentes à assumer les frais de rénovations importantes. Intégrer des éléments propriétaires dans la conception d'origine d'un bâtiment signifie que les entreprises trouveront plus facile d'ajuster leurs espaces en réponse aux progrès de la technologie ou aux changements dans les priorités opérationnelles. En anticipant les tendances futures de l'industrie telles que les espaces de bureaux flexibles et la durabilité, les entreprises peuvent construire des structures durables qui permettent des changements de fonction et une résistance à un environnement difficile.

Intégration des technologies énergétiquement efficaces et intelligentes

Le rôle des concepts énergétiquement efficaces et intelligents dans la conception des structures en acier. L'utilisation de matériaux et de technologies économes en énergie et intelligentes dans les structures en acier apporte des avantages pertinents à long terme. Ces outils, y compris les panneaux solaires et les capteurs intelligents, améliorent la productivité et aident à atteindre les objectifs de durabilité. Les applications de construction intelligentes contrôlent automatiquement les services tels que l'éclairage et la température, ce qui contribue à minimiser la consommation d'énergie et les coûts d'exploitation. Malgré tous ces avantages, le plus évident : réduire les factures d'énergie et diminuer les émissions de CO2, est peut-être la meilleure raison d'adopter des conceptions économes en énergie. Dans le cas des constructions en acier, cela signifie également qu'une combinaison de durabilité et des dernières technologies intelligentes est parfaitement adaptée pour des solutions efficaces, économiques et durables dans une variété d'industries.

FAQ

Quels facteurs doivent être pris en compte lors de la conception d'une structure en acier ?

Lors de la conception d'une structure en acier, il est important de prendre en compte l'objectif principal de la structure, des facteurs spécifiques à l'emplacement comme le climat et la stabilité du sol, les besoins en portance et en utilisation de l'espace, ainsi que la conformité avec les normes locales et internationales. Il faut également prendre en compte la scalabilité future, l'adaptabilité et l'intégration de technologies énergétiquement efficaces.

Quels sont les avantages du design modulaire dans les structures en acier ?

Le design modulaire dans les structures en acier offre une flexibilité, permettant une expansion scalable sans rénovations importantes. Il fournit une adaptabilité aux entreprises pour ajuster leurs espaces selon les besoins opérationnels, facilitant des réponses rapides aux dynamiques de marché changeantes et aux exigences opérationnelles.

Comment puis-je m'assurer de la sécurité structurelle d'un bâtiment en acier ?

Pour garantir la sécurité structurelle, collaborez avec des ingénieurs structurels certifiés pour évaluer les besoins en ingénierie et vous assurer de la conformité avec les normes de sécurité. Réalisez des calculs de charge précis, concevez des joints fluides et respectez les normes internationales de construction telles que celles établies par l'AISC. Cela garantit l'intégrité structurelle et la longévité du bâtiment.

Pourquoi les revêtements résistants à la corrosion sont-ils importants pour les structures en acier ?

Les revêtements résistants à la corrosion sont essentiels car ils prolongent la durée de vie des structures en acier en les protégeant contre les éléments environnementaux. Ils minimisent les besoins en entretien et en réparation, réduisant ainsi les coûts à long terme. Des revêtements tels que la galvanisation ou le sablage offrent une protection adaptée en fonction des conditions environnementales.

Table des Matières

- Évaluation des besoins de votre entreprise pour la conception de structures en acier

- Facteurs Spécifiques au Lieu dans la Construction de Structures en Acier

- Sélection de matériaux en acier et de revêtements de haute qualité

- Conformité de l'ingénierie et de la conception pour la sécurité structurelle

- Personnalisation et anticipation de votre ossature en acier

-

FAQ

- Quels facteurs doivent être pris en compte lors de la conception d'une structure en acier ?

- Quels sont les avantages du design modulaire dans les structures en acier ?

- Comment puis-je m'assurer de la sécurité structurelle d'un bâtiment en acier ?

- Pourquoi les revêtements résistants à la corrosion sont-ils importants pour les structures en acier ?