অংশবদ্ধ স্টিল সমর্থন

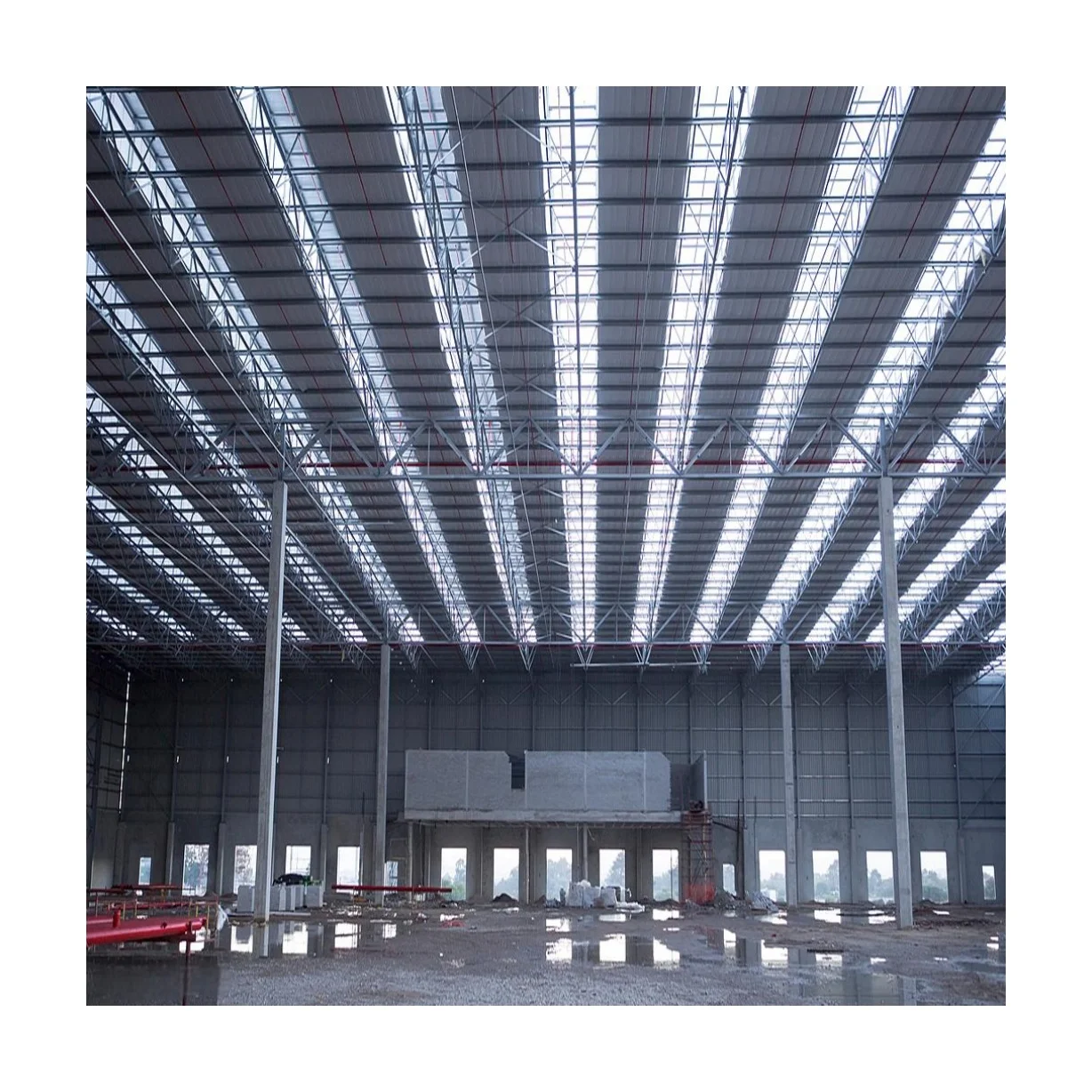

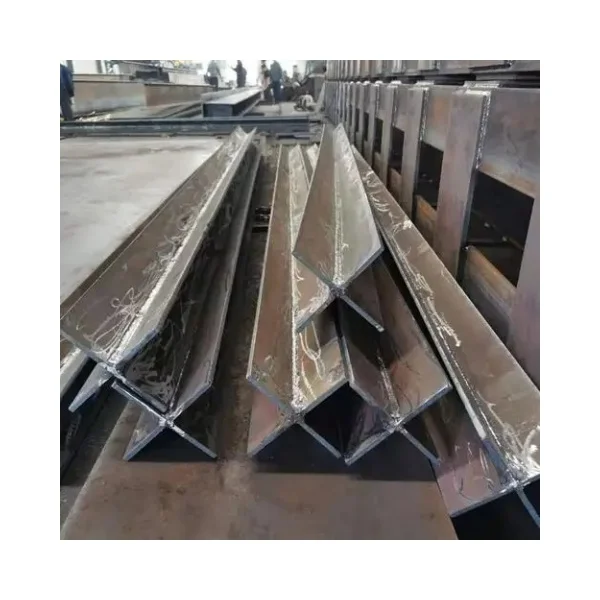

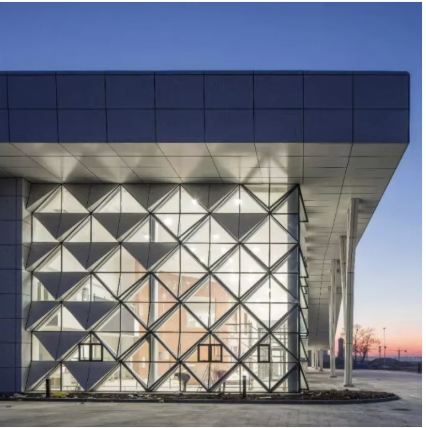

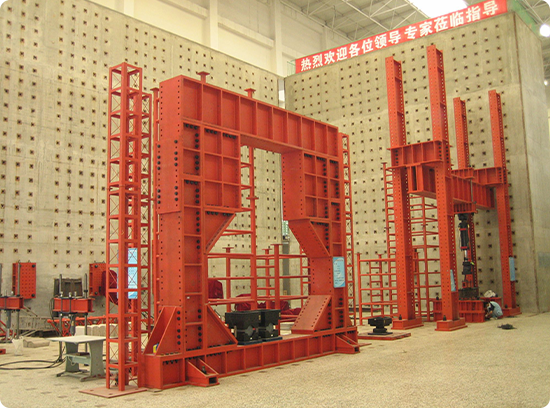

মডিউলার স্টিল সাপোর্ট কনস্ট্রাকশন এবং ইনফ্রাস্ট্রাকচার উন্নয়নে একটি বিপ্লবী উন্নতি প্রতিনিধিত্ব করে, যা বিভিন্ন স্ট্রাকচারাল অ্যাপ্লিকেশনের জন্য একটি বহুমুখী এবং দৃঢ় সমাধান প্রদান করে। এই উদ্ভাবনী সিস্টেমটি উচ্চ-শক্তির স্টিল উপাদান এবং নির্দিষ্ট প্রকৌশলের সংমিশ্রণ করে গঠন করেছে যা প্রয়োজন অনুযায়ী সহজে আরোপ করা, পরিবর্তন করা এবং বিশ্লেষণ করা যায়। সিস্টেমটি লোড সমানভাবে বিতরণ করতে পারে এমন ইন্টারলকিং স্টিল মডিউল দ্বারা গঠিত, যা বিভিন্ন অ্যাপ্লিকেশনে স্ট্রাকচারাল পূর্ণতা বজায় রাখে। প্রতিটি উপাদান শক্তিশালী গুণবত্তা নিয়ন্ত্রণের মাধ্যমে যাচাই করা হয় এবং টিকেটে এবং করোশন রিজিস্টেন্স নিশ্চিত করতে বিশেষ কোটিং ট্রিটমেন্ট ব্যবহৃত হয়। মডিউলার প্রকৃতি কনস্ট্রাকশন প্রজেক্ট, শিল্প ফ্যাসিলিটি এবং সাময়িক সাপোর্ট অ্যাপ্লিকেশনে দ্রুত বিকাশের অনুমতি দেয়। সিস্টেমের ডিজাইনে উন্নত ভারবহন গণনা অন্তর্ভুক্ত রয়েছে, যা একে উল্লেখযোগ্য উল্লম্ব এবং পার্শ্ব বল সহ সহ্য করতে দেয় এবং অপটিমাল স্থিতিশীলতা বজায় রাখে। এই সাপোর্টগুলি বহুমুখী ব্যবস্থায় কনফিগার করা যেতে পারে, যা এগুলিকে স্থায়ী এবং সাময়িক ইনস্টলেশনের জন্য উপযুক্ত করে। মডিউলার স্টিল সাপোর্টের পেছনের প্রযুক্তি অন্তর্ভুক্ত রয়েছে উদ্ভাবনী সংযোগ মেকানিজম যা ভবিষ্যদের পরিবর্তন বা বিস্তৃতির অনুমতি দেয় যখন প্রজেক্টের প্রয়োজন বদলে।