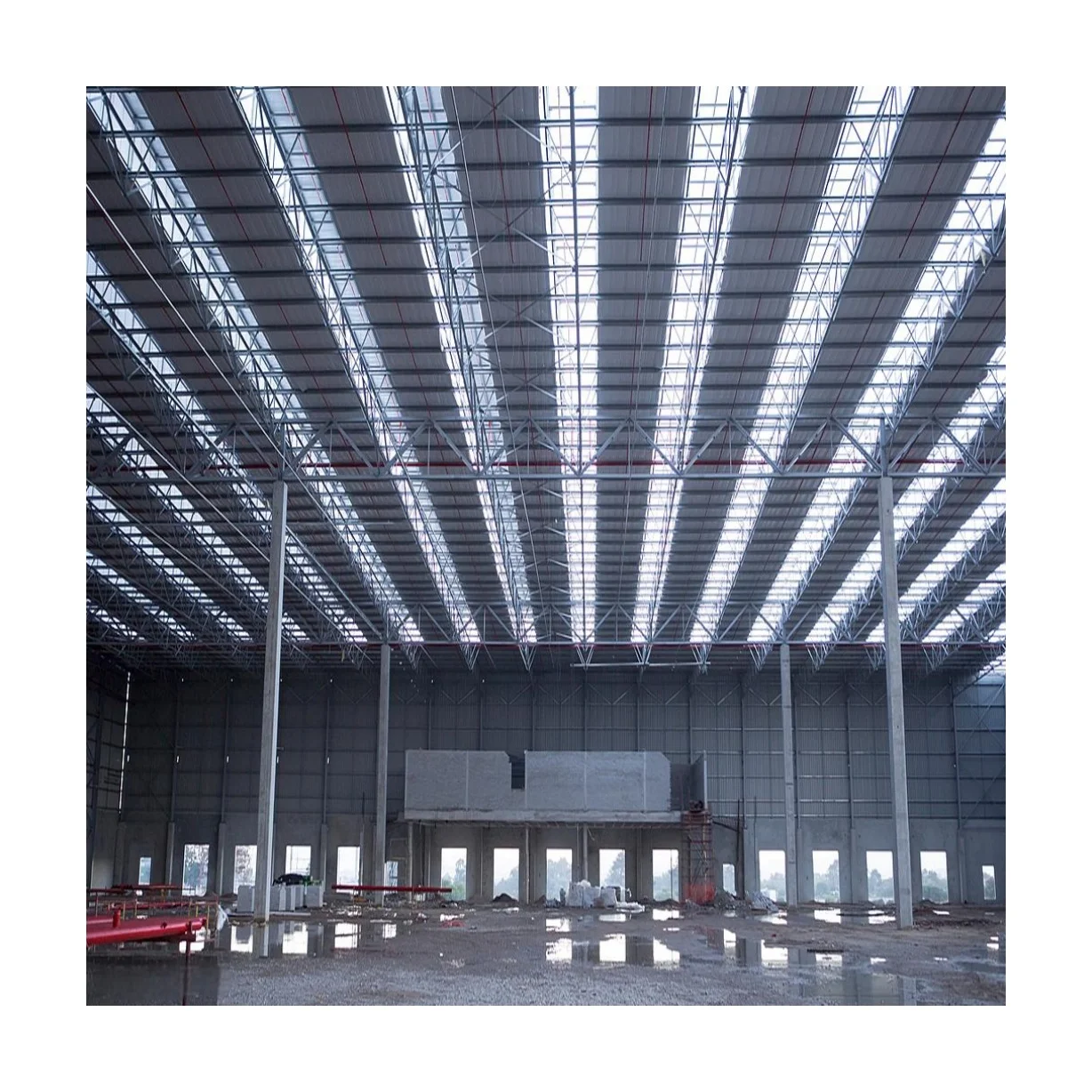

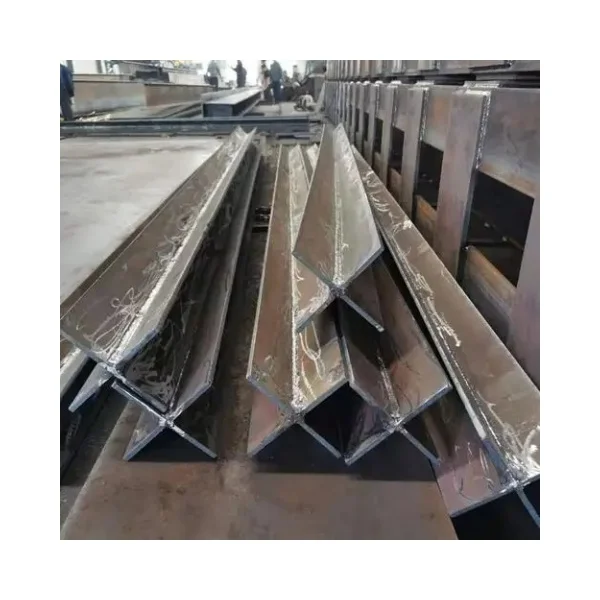

أهم الأسباب لاختيار الهياكل الفولاذية للactories الحديثة

أهم الأسباب لاختيار الهياكل الفولاذية للactories الحديثة شهدت صناعة البناء تغيرات ملحوظة في العقود الأخيرة. ومع تطور الهندسة والتكنولوجيا وممارسات الاستدامة، لم تعد الactories تُبنى كما كانت من قبل...

عرض المزيد