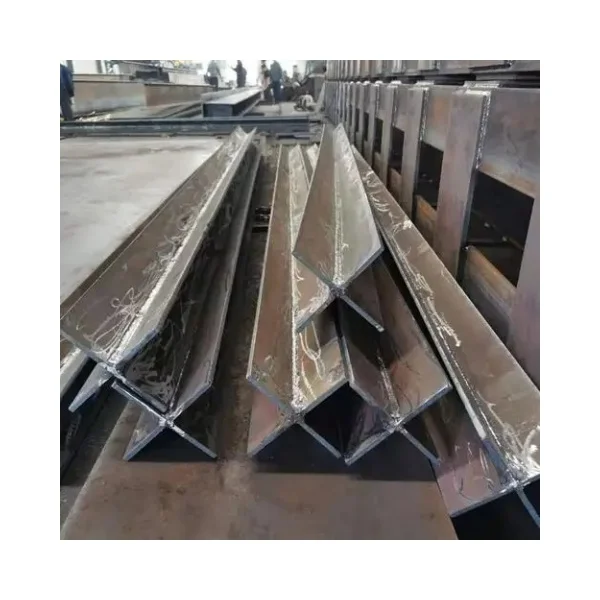

thrust frame

A thrust frame represents a critical structural component in mechanical engineering, specifically designed to manage and distribute thrust forces in various industrial applications. This robust framework serves as the primary support system for managing axial loads and maintaining operational stability in equipment ranging from aerospace propulsion systems to industrial machinery. The thrust frame's sophisticated design incorporates high-strength materials and precision engineering to effectively handle both static and dynamic loads while minimizing vibration and structural stress. Its construction typically features reinforced mounting points, integrated cooling systems, and advanced load-bearing surfaces that work in concert to optimize force distribution and enhance operational efficiency. The frame's architectural integrity is maintained through strategic placement of support members and load-bearing components, ensuring consistent performance under varying operational conditions. Modern thrust frames often incorporate smart sensors and monitoring systems that provide real-time data on structural integrity, load distribution, and performance metrics, enabling proactive maintenance and operational optimization. These frames are customizable to specific applications, with various sizes and configurations available to meet diverse industrial requirements, from small-scale manufacturing equipment to large industrial turbines.