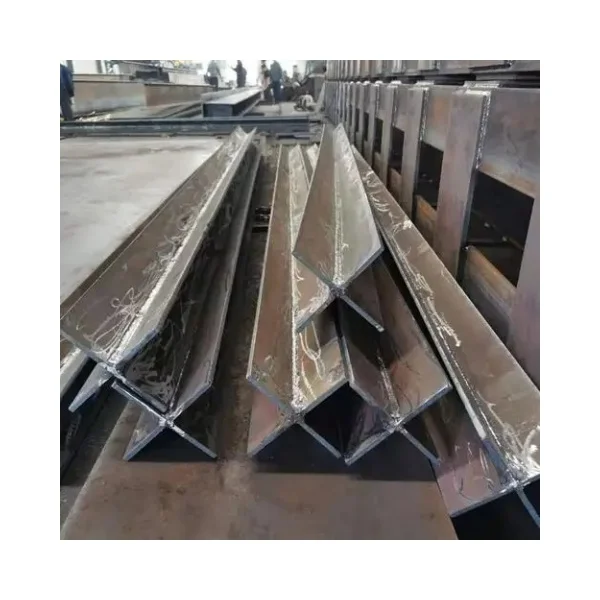

steel frame support

Steel frame support systems represent a cornerstone in modern construction and industrial applications, offering unparalleled structural integrity and versatility. These robust support systems comprise precision-engineered steel components designed to bear substantial loads while maintaining optimal stability. The primary function of steel frame supports lies in their ability to distribute weight evenly across structural points, preventing stress concentration and ensuring long-term durability. Their technological features include advanced welding techniques, corrosion-resistant coatings, and modular designs that facilitate easy installation and maintenance. In industrial settings, steel frame supports are extensively utilized in warehouse construction, equipment mounting, and heavy machinery foundations. The systems incorporate adjustable components that allow for precise leveling and alignment, making them ideal for various applications across different industries. Modern steel frame supports also feature innovative stress-distribution technology that enhances their load-bearing capacity while minimizing material usage, resulting in cost-effective and environmentally conscious solutions. These supports are engineered to meet stringent safety standards and building codes, ensuring reliable performance under diverse conditions.